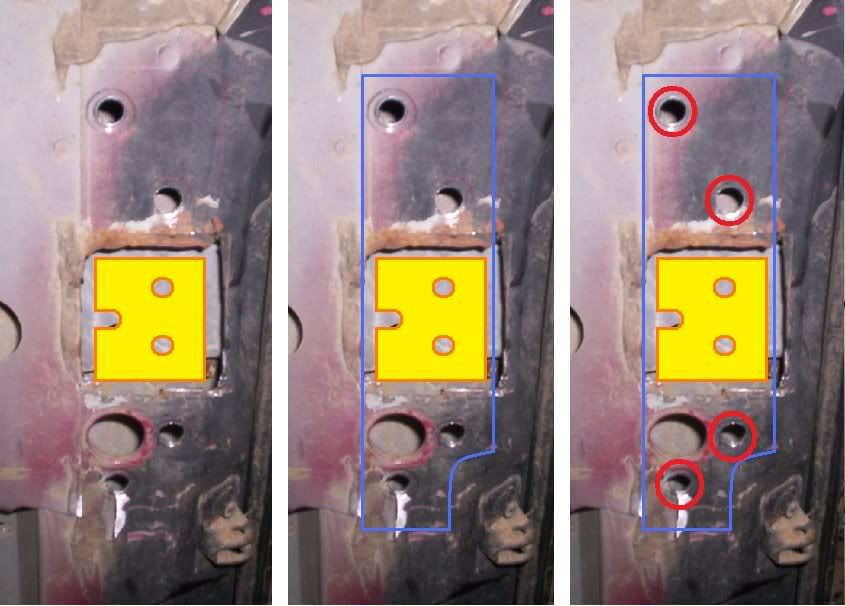

Like many XJs (especially the two-doors) my driver's door has sagged badly for years. Last week, the damn thing finally fell off in the driveway. That's how I know it's time to fix something.

For those that don't know, the problem stems from AMC's lame-brained idea of welding the hinge to the sheet metal unibody (bad enough) and then neglecting to weld the rear edge (even worse.)

As those welds start to crack, the hinge separates from the body, and the door sags. Eventually, the hinge can break all the way off, and you're done.

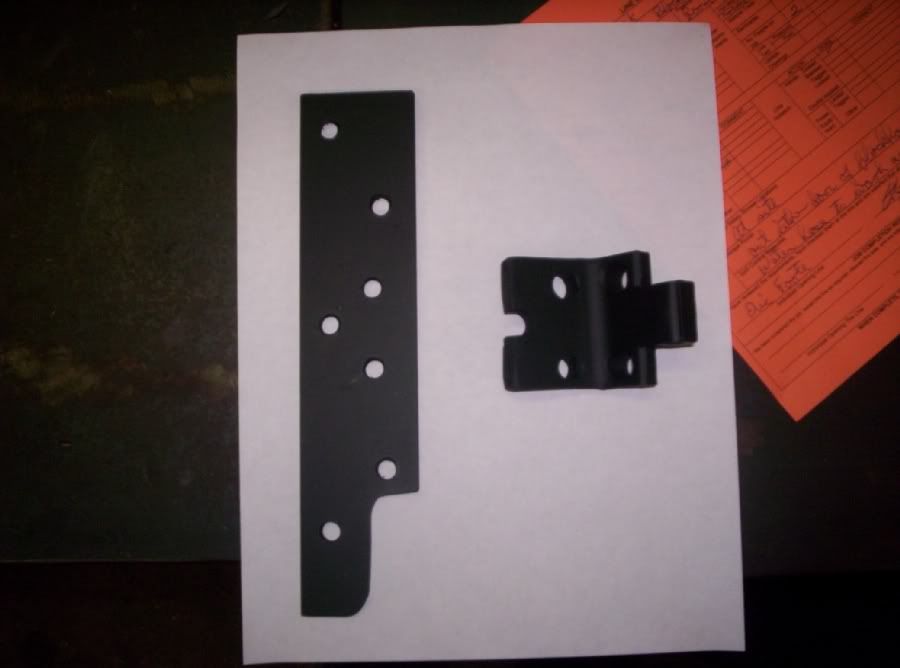

I'm a pretty mediocre welder. I can stick plate to plate pretty well, and sheet to sheet pretty badly. But sticking the ~3/8" hinge back onto the cracked, rusty sheet metal just wasn't going to happen for me.

I considered paying a friend to do it, but he was busy and I was broke. So I came up with this...

For those that don't know, the problem stems from AMC's lame-brained idea of welding the hinge to the sheet metal unibody (bad enough) and then neglecting to weld the rear edge (even worse.)

As those welds start to crack, the hinge separates from the body, and the door sags. Eventually, the hinge can break all the way off, and you're done.

I'm a pretty mediocre welder. I can stick plate to plate pretty well, and sheet to sheet pretty badly. But sticking the ~3/8" hinge back onto the cracked, rusty sheet metal just wasn't going to happen for me.

I considered paying a friend to do it, but he was busy and I was broke. So I came up with this...

Yeah, then you just drill the body-side hole out to 7/16 to clear the 3/8 bolt.

Yeah, then you just drill the body-side hole out to 7/16 to clear the 3/8 bolt.

Comment